R&D and Production

Production and Assembly Line

We implement products whose R&D has been completed, bringing them to life with our professional staff within the framework of quality standards.

Our production line is equipped with all types of hand tools required for UAV assembly. Fastening of components is performed using torque-controlled pneumatic tools. We secure bolts ranging from M2 to M10 according to the quality standards specified for use in your products.

The assembly of our electronic products is carried out in an ESD-protected environment.

Manufacturing

Our manufacturing processes are conducted in accordance with aerospace and defense industry quality policies

- Sheet Metal Processing

- Welding

- Machining

- Pressing

- Paint Shop

Our sub-units are equipped with an advanced machinery park

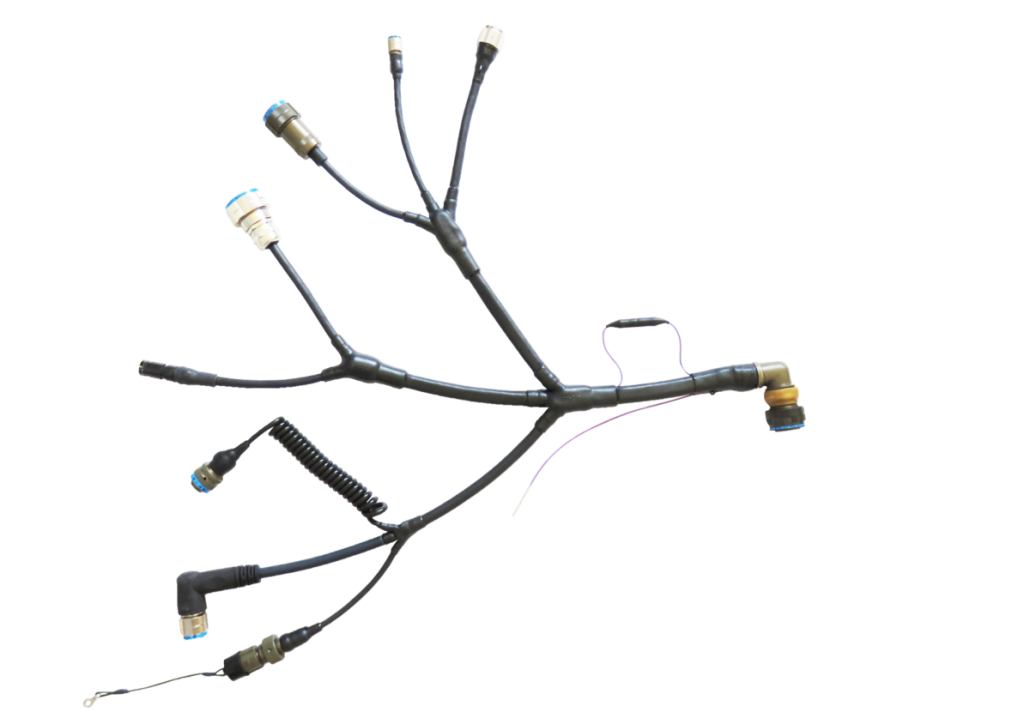

Cabling

For domestic and international projects, we are able to prepare cabling and connectors for large- and small-scale projects designed for military and civilian purposes.

Our Cabling Capabilities:

- Cable Preparation

- Cable Cutting and Stripping

- Crimp Terminal Assembly

- Cable Harnessing

- Cable Harnessing Methods

- Binding with Cable Ties

- Overhand Knot

- Surgeon's Knot

- Securing with Cable Ties

- Cable Harness Branching Types

- “ T “ Branching

- Cross Branching

- Broom Bundle

- Connector Connections

- Service loop

- Heat Shrink Tubing Installation on Terminals

- Friction Protection

- Cabling Applications

- Inspection of Cabling Applications (Quality Control)

In military, civilian, medical, and industrial sectors, cabling production is carried out with expertise that ensures uninterrupted serial production, taking customer requirements into account and adhering to the specifications mentioned above.